Plastics industry robots

Turnkey Robotics Solutions Efficiency, Flexibility & Safety

Our automation solutions integrate seamlessly with blow and injection molding machines to streamline machine tending, packaging, and material handling. Designed for flexibility, our plastics industry robots adapt to production changes with minimal effort, enhancing efficiency while ensuring workplace safety.

Adjust Quickly as Production Changes

Our systems deliver cutting-edge motion control and vision technologies that allow extreme precision that keeps up with your production volume.

Keep up with changing production demands by reprogramming and redeploying our robots with minimal effort.

- Reconfigure robots easily for new SKUs, molds, and packaging formats.

- Swap end-effectors quickly to handle different parts and container types.

- Move systems effortlessly between compatible blow molding machines with locking casters and pin locators.

Integrate Directly with Your Existing Machines

Eliminate the need for additional engineering with automation designed specifically for plastics production.

- Connect seamlessly with blow and injection molding machines for automated part removal and handling.

- Sync with existing conveyors and downstream packaging systems to maintain workflow efficiency.

- Set up quickly with standard electrical and pneumatic connections, reducing installation time and costs.

Improve Workplace Safety

Reduce worker exposure to high-temperature plastics and repetitive tasks with built-in safety features.

- Utilize interlocking guarding doors and emergency stops to maintain a safe work environment.

- Deploy collaborative robots (cobots) that work alongside operators without extensive guarding.

- Automate part handling to minimize manual intervention, reducing injury risks.

Streamline Operation with User-Friendly Automation

Our robotics solutions are designed for effortless operation, allowing you to automate processes without requiring robotics or engineering expertise.

- Simplify daily operations with an intuitive HMI interface and easy-to-follow controls.

- Deploy automation quickly with preconfigured settings and guided setup, reducing reliance on specialized engineers.

- Minimize maintenance and downtime with reliable, low-upkeep systems for continuous production.

Maximize Mobility & Scalability

Keep production flexible with robotic solutions that move and expand as your business grows.

- Relocate robots easily between compatible blow molding machines to maximize asset utilization.

- Expand automation effortlessly with modular systems that scale alongside your operations.

- Optimize floor space with compact robotic cells designed for high efficiency in small footprints.

Featured Products

Explore our advanced automation solutions to enhance plastics manufacturing efficiency, flexibility, and scalability.

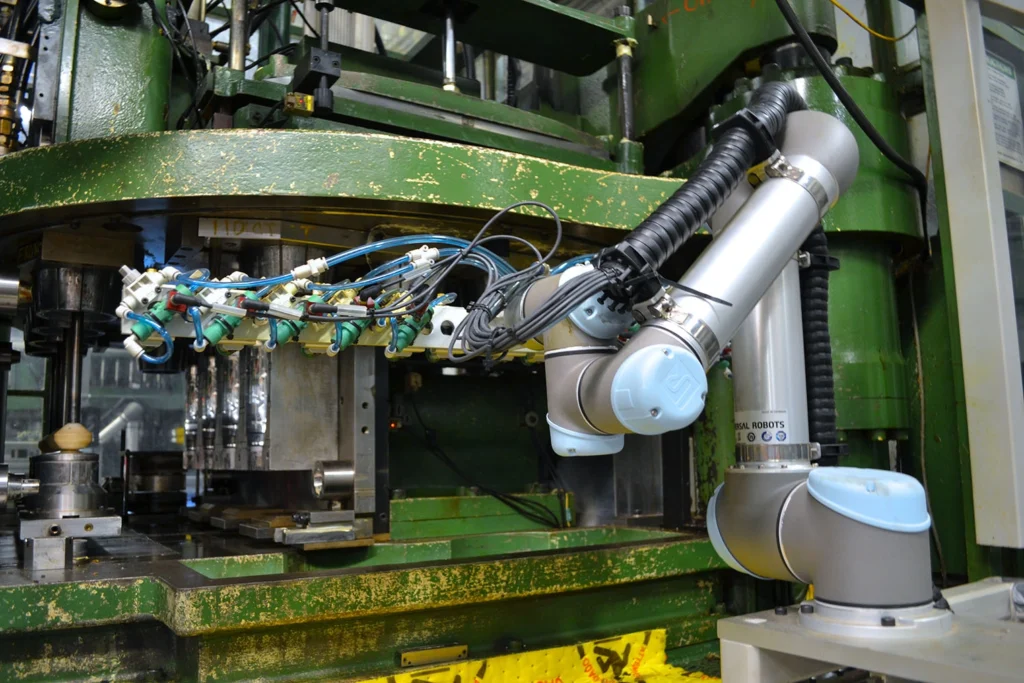

Machine Tending - Takeout Robot

This turnkey robotic system automates part removal from blow and injection molding machines, streamlining production with minimal manual intervention. Designed for flexibility, our takeout robots adapt to different machine models and SKUs. A quick-change end-effector, intuitive interface, and low-maintenance design ensure seamless operation. Watch how it works.

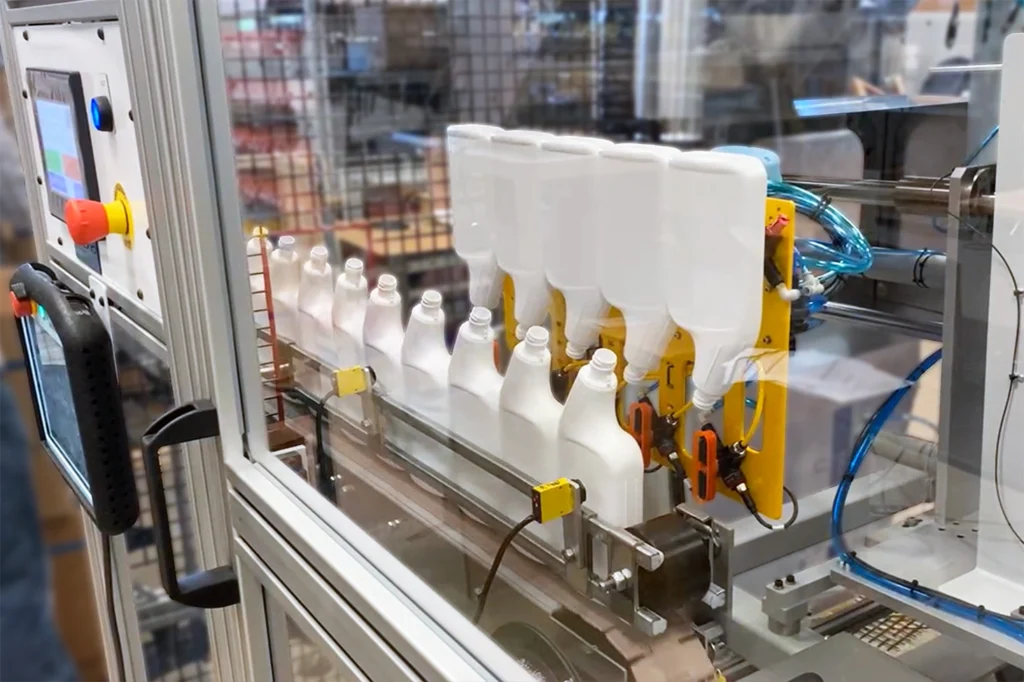

Case Packer Robotic Cell

This automated packaging solution optimizes box packing for custom plastic parts and containers. Featuring a collaborative robot (cobot) and automated box presentation, it efficiently handles unique shapes and sizes. Integrated safety, real-time throughput tracking, and a user-friendly interface make it ideal for high-mix production environments. Watch how it works.

Custom Machines

Our custom automation solutions address your plastics manufacturing challenges, combining advanced robotics, motion control, and precision engineering.

Future-Proof Your Aerospace Manufacturing Operations

Designed and built in Exton, PA, our turnkey automation solutions address the unique challenges of aerospace manufacturing by improving precision, efficiency, and safety. From eliminating operator fatigue and material handling issues to ensuring repeatable accuracy in complex machining and composite fabrication, our systems enhance productivity while reducing costs. Whether you need a fully customized robotic solution or a scalable automation system, we deliver technology that adapts to your evolving production demands.

Take the next step toward a safer, more efficient aerospace manufacturing process. Contact us to discuss your automation needs.